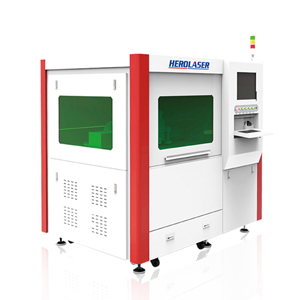

Shenzhen Herolaser Equipment Co., Ltd was established in 2004, is a national high-tech enterprise in China, engaged in the

research and development, production and marketing of laser equipment group of companies, has formed a complete series of

industrial laser equipment supply platform.

With a team of professional technical personnel,rich management experience, clear development direction to ensure our rapid growth

in the rapid development of the laser industry,we have established branches in Jiangsu, Zhejiang,Shandong, Chongqing and other

regions in China, and we have exported to 60 countries and have overseas agents in 10 countries. Our main products is Laser

Cleaning Machine / Laser Marking Machine / Laser Welding Machine / Laser Cutting Machine.

Products are widely used in electrical appliances, mobile communications, hardware products, tool accessories, precision

equipment, jewelry, glasses and watches, integrated circuits, craft gifts, plastic molds, medical equipment and other industries.

Laser cleaning machine is the latest high-tech product. Easy to install, operate, easy to achieving automation. Plug in power, turn on and start cleaning - without chemicals, media, dust, water.

Cleaning with no detergent, no media, no dust, no water. Auto focus, can clean curved surface, gentle cleaning surface. Cleaning resin, oil stain, rust, coating materials, paints on workpiece surface.